![]()

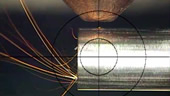

Northeast Laser & Electropolish provides contract laser welding services, laser marking services, laser cutting services and laser engraving services to companies throughout the United States, and is one of the only laser job shop facilities with an in-house electropolishing and passivating division. Our goal is to be your preferred source by delivering a superior level of quality, value and customer interaction. An around-the-clock operation, validated processes, unmatched capacity and supply chain management are just some of the reasons to partner with Northeast Laser.

Laser Marking, Welding, Cutting, and Engraving as well as Electropolishing and Passivating

- Medical Components and Sub-Assemblies

- Precision Industrial Components

- Surgical Instruments including cannula, trocar, catheter and guide wires

- Industrial, Sensor and Telecommunication Parts

- Supply Chain Management

- Panel and Dial Marking

- Mold Core and Tool Engraving

- Laser Ablation and Texturing (an alternative to bead-blasting)

- Highly Decorative Products including firearms and firearm components

- Surface Mount Components

- Almost all Metals, Plastics, Ceramics, Wood etc.

Prototype to High Production. Validated Processes. ISO Certified

- Streamlined Operations: Laser Marking & Engraving, Laser Welding, Laser Cutting, Electropolishing & Passivation in one facility. This means faster turnaround times for your company

- The most advanced laser marking, welding and cutting equipment ensures high quality results

- Calibrated Banding, Date Coding, Logo Placement—precise and accurate

- Vision directed weld stations allow fast and accurate processing and ease of validation

- Superior Proprietary Corrosion Resistant Marking—longer life, reduces cost

- Laser Cutting of complex geometries

- Largest and fastest steered beam laser markers (32'' x 32'') for large area processing

- Deep Engraving (0.005'' to 0.030''+) for wear-resistance

Our range of applications is unparalleled and constantly expanding. Call us with your next project and discover why our customers return to us, and recommend us - again and again. See more!

Be sure to stop by our booth while we're exhibiting at BIOMed Boston